The outcome of a NSW Department of Primary Industries (DPI) study into why subtropical bananas may be rejected at retail outlets has led to the development of a new banana packing poster.

The Subtropical Packed Product Analysis was carried out in Coffs Harbour, northern NSW, and looked at fruit ripening to see what issues were causing fruit to be rejected at retail outlets.

Earlier, a survey of NSW banana growers found very few investigated the causes of packed or rejected fruit so they could implement measures to reduce or eliminate quality issues.

NSW DPI Industry Development Officer Tom Flanagan said fruit was assessed at Golden Dawn, a major banana ripening and wholesale company in the Coffs Harbour region.

“Assessments were made on fruit supplied by 12 banana growers, consisting of 71 cartons that contained a total of 709 clusters,” Mr Flanagan said.

“Fruit was checked against the most recent specifications released by a major retailer.

“The specifications relate to ‘total minor defects’ of a consignment (%) and ‘total major defect rates.

If defects exceed the specified rates, retailers can pay suppliers less for their fruit or reject the consignment entirely.”

The study found 38 per cent of all clusters inspected were deemed to have either a major or minor defect, more than three times above specifications.

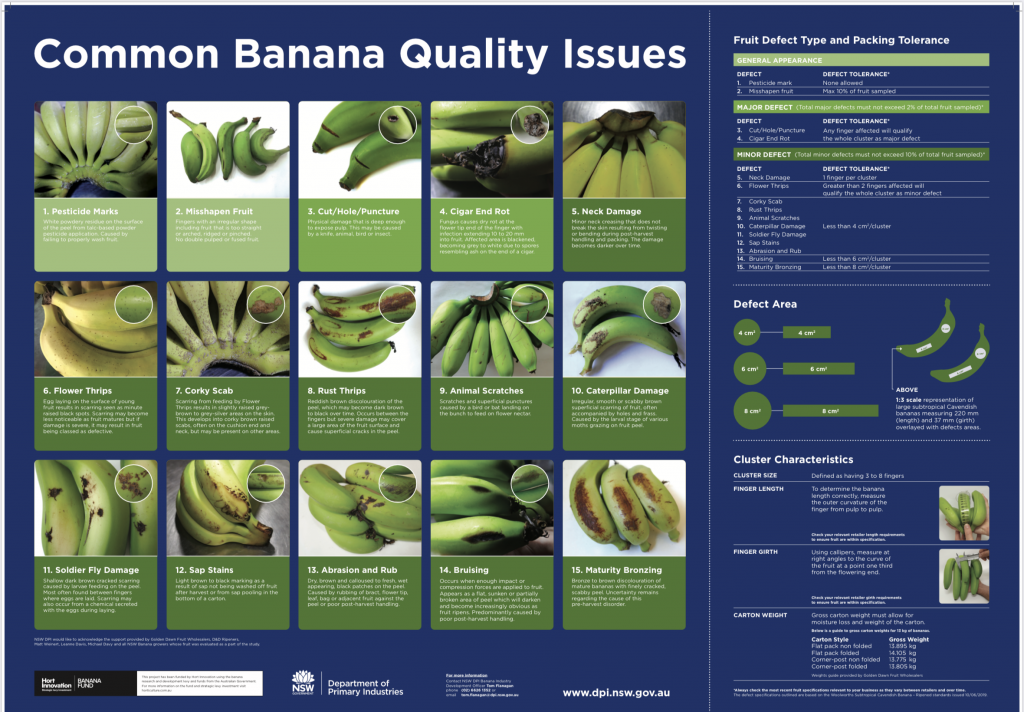

Minor defects included abrasion, thrips damage, bruising, rub and dry scars.

Major defects included a cut, hole or puncture, pesticide residue and immature or thin fruit.

“The findings show that too much fruit with major or minor defects is being packed,” Mr Flanagan said.

“This is increasing the risk of consignments being rejected or their value reduced.”

As a result of the study, a new banana packing poster has been developed, outlining common banana quality issues.

Mr Flanagan said there were simple, cost-effective changes that could be made in the paddock, packing shed and supply chain to improve the quality of fruit and increase profitability for growers.

He said a cut, hole or puncture through to the pulp of the fruit was the most common major defect found in the study, followed by white residue from talc-based pesticides.

“It is possible to reduce the frequency of these issues with appropriate post-harvest handling and packing strategies,” Mr Flanagan said.

“For example, washing fruit thoroughly prior to packing will remove any pesticide residue, whereas increased screening for underdeveloped fruit, or using callipers to check girth, would prevent thin and immature fruit from being packed.

“When applied to the data from this study, employing these two simple strategies could reduce the occurrence of major defects by 45 %.”

Mr Flanagan said post-harvest handling was an area where small changes to equipment, techniques and practices can have a large impact on fruit quality.

“Changes to post-harvest handling on your farm should be investigated to determine whether small, cost-effective changes can be easily implemented to help decrease defects, increasing quality and ultimately profitability,” Mr Flanagan said.

Growers interested in getting a copy of the packing poster can contact Tom Flanagan on 02 6626 1352 or [email protected]