A recent round of audits by Workplace Health and Safety inspectors on banana farms in the Cassowary Coast prompted some immediate concern by growers over ‘grey areas’ within WH&S regulations and the necessity of some requirements.

Here – with the assistance of WH&S consultant Craig Althaus of AgSafe Advisory Services – we attempt to outline some of the compliance

issues where growers have been issued improvement notices and dissect current legislation. Sonia Campbell reports.

The primary aim of developing a system to manage health and safety risks on a property is to protect workers’ health; keep workers safe from injury or greater harm; and to protect business owners from avoidable compensation payouts, litigation and/or criminal charge.

There is little doubt every grower wants to keep their workers and their workplaces safe, and the vast majority in the banana industry do their best to ensure this is the case.

However, the complexities of Work Health and Safety Regulations can often be tricky waters to navigate.

Firstly, there is generally no hard or fast rules for what constitutes compliance to the WH&S framework, as many of the regulations come down to an individual business owner gauging their level of compliance, by conducting their own risk assessments.

Some growers argue that it is not a case of not wanting to comply with some regulations, instead the ambiguous nature of WH&S rules means in many cases they simply don’t know how.

Secondly, some regulations are arduous and require significant cost to the grower. One example – which most growers were previously unaware of – is the continual upkeep and repair of bagging machines, which require a ‘major inspection’, including full stripdown and re-build, by a qualified person every 10 years.

In July, the Australian Banana Growers’ Council organised two workshops at Silkwood and Mareeba for growers to express concerns over WH&SQ audit processes and some regulatory requirements – particularly in relation to bagging machines – and to have them addressed by Craig Althaus and Far Northern-based WH&S inspector Adam Spinelli.

Some growers have questioned the need for bagging machines to be fitted with safety harnesses (or positioning belts) believing it would pose a safety risk to the operator if the machine rolled or fell to the ground.

The harness regulation was a direct result of a Coroner’s recommendation following an inquest into the death of a bagging machine operator in Far North Queensland in 2004. Mr Althaus said harnesses (restraints) could be equipped with a quick release system and were designed to prevent operators falling from bagging machine baskets.

DISSECTING CURRENT WH&S LEGISLATION

MOBILE ELEVATED WORK PLATFORMS (BAGGING MACHINES)

All banana bagging machines must be fitted with a fall restraint system, to prevent the risk of falls from banana bagging machines.

There is no specification under WH&S legislation on what type of fall restraint is needed for compliance, however one suggested option is a positioning belt (see pic 1) – with either one or two tethers– which can be connected to a certified anchor point on the bagging machine.

Craig Althaus said if an existing anchor point is not labelled as certified, an anchor point must be engineer certified and retro-fitted by a qualified person.

“The tether attached to the anchor and positioning belt needs to be a length whereby the worker cannot exit the basket… they cannot get up on the rail … essentially it is to stop the worker being ejected from the machine,” Mr Althaus said.

Howe Farming Group at Walkamin in Far North Queensland has undertaken extensive trials of restraint systems in their bagging machines.

General Manager Kim Mastin said the company had found that a positioning belt with two tether points was the most effective.

“We found one tether at the front and one from the back was the best, to avoid them (workers) being able to fall out, backwards or frontwards,” Ms Mastin said.

“At the moment we’ve seen no operational issues with this system and the lanyards that we’ve put into place and we are purely just waiting for more to be built, otherwise all our fleet will be done.

“It’s 100 per cent about safety. We don’t want injuries, we want them to be able to work and be happy.”

RISK OF FALLS FROM LOADING DOCK FACILITIES

Measures must be taken to prevent workers from falling from loading docks. This can be done with either a fixed gate system, or in low traffic areas, simply use a yellow chain. (See pic 3)

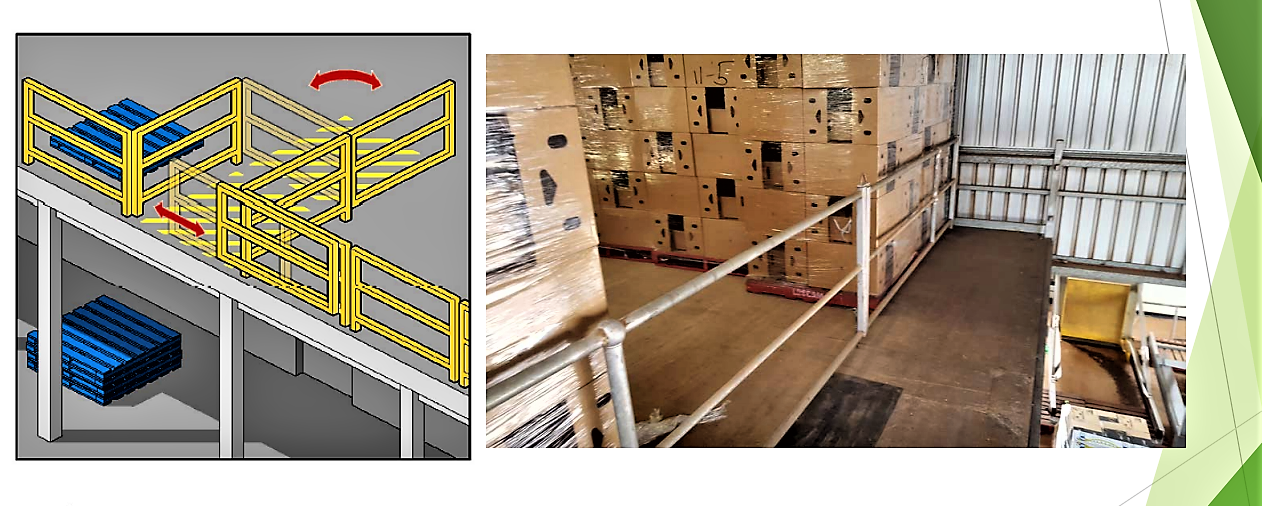

RISK OF FALLS FROM MEZZANINE FLOORS

The risk of falls from mezzanine floors should be controlled with fixed railings and gates to access storage areas where needed. (See pic 4)

FIRST AID

“Farmers must have an adequate number of workers trained to provide first aid at the workplace,” Mr Althaus explained.

“The number of first aiders will vary depending on the size of the business – geographically – and the number of people working on-site. It will come down to doing your own risk assessment,” he said.

Workers must also be provided with first aid equipment. Generally, the main first aid kit will be in the packing shed, but workers outside also need to have access to basic first aid equipment – stored either in vehicles, quad bikes or tractors – to treat snake bites, deep wounds and sprains.

TRANSPORTING WORKERS IN THE FIELD

The common practice of transporting people/workers on trailers and in the back of utes is illegal under WH&S regulation.

This is because there is no control against workers being ejected from the vehicle or trailer.

“Growers can purchase a trailer specially designed to carry workers in the field. It needs to be fitted with seats belts, certified by an engineer and be constructed by a competent person.” Mr Althaus said.

“A cheap commuter bus could also be a possible option.”

HEAT RELATED ILLNESS

Growers must provide information, instruction and training around managing heat-related illnesses.

This includes effective ways to prevent the onset of heat illness, by providing ice and water in the field, encouraging breaks in shaded areas and rotating tasks for new workers and allowing time for workers to acclimatise to a tropical region.

“For example, if you did have a worker who has just arrived from a northern European country, you would initially assign them less strenuous tasks, like tractor driving or shed work and then work up to more strenuous activities over time, say a month, where you would expect them to be able to handle the rigors of humping bananas,” Mr Althaus said.

Supervisors and managers must be trained to recognise the symptoms of heat related illness and prevent the condition from worsening.

PALLET STACKERS

An effective way to prevent entry (and injury) under pallet stackers is a movable gate that is put in place when the machine is in use. (See pic 5)

GUARDING ON CONVEYOR BELTS

Guarding should be installed on conveyor belting to prevent a worker getting body parts caught or clothing and hair entangled in the conveyor belt.

COMMUNICATING WITH WORKERS

Growers must have a means of communicating with all workers, even those working in isolated areas. This can be accomplished either through mobile phones (if there is effective coverage) or portable UHF. There is also a variety of rescue Apps available online.

INDUCTION TRAINING

All workers must be provided with effective induction training. This includes not only showing them how to do their job but be supervised to ensure that they are doing their job in the correct manner and safely.

If a worker is non-English speaking, induction and training must be delivered in the manner they understand.

Growers must be satisfied that all workers can complete tasks safely and correctly after they are trained.

This training must be also be documented. This needs to be signed by the worker and supervisor.

“Yellow Card is an induction course worker can do online. It is translated into eight languages including English, Korean, Tongan, Samoan, French, Chinese and Japanese. This is an in-depth safety induction into the banana industry. It’s free to the grower, the worker pays for the course and can undertake it prior to employment and not have to go through such an extensive on-farm safety induction when they start. It saves a grower about half an hour per worker in training.”

FARM SPECIFIC TRAINING AND SUPERVISION

Growers must provide a site-specific induction, which covers information about hazards specific to their farm, such as cane rail crossings, the presence of crocodiles and other safety related issues.

Again, all safe work procedures need to be clearly understood by the employee. If the worker does not speak English, growers must be able to verify the worker’s level of understanding and be sure that all workers understand the work and can complete tasks safely.

MAINTENANCE AND INSPECTION OF MOBILE ELEVATED PLATFORMS (EWP) INCLUDING BAGGING MACHINES

All Mobile Elevated Work Platforms (MEWPs), including bagging machines, must have pre-operation or daily checks. They must also have routine or pre-harvest inspections (200 hourly or as per the manufacturers’ guidelines) as well as an annual third party inspection.

A major 10-yearly inspection is also required. This involves a strip-down, through inspection and re-build of the EWP, checking all structural components for cracks, corrosion and damage.

Forklifts require the top three checks – daily, routine/pre-harvest and third party.

“Any agricultural safety management system has to be reviewed and updated constantly and you have to have someone maintaining it. For example, you need to keep records up to date, ensure training is completed and all your inspections are completed,” Craig Althaus.

For further information on farm WH&S regulations go to;

www.worksafe.qld.gov.au

www.farmsafe.org.au

https://www.worksafe.qld.gov.au/__data/assets/pdf_file/0006/83778/5564-serious-aboutfarm-safety.pdf

Growers also have access to the Injury Prevention and Management (IPaM) program, a joint initiative between Workplace Health and Safety Queensland (WHSQ) and WorkCover Queensland, designed to help businesses develop better WH&S and injury management systems.

Craig Althaus can be contacted by phoning 0429 682 206 or email [email protected]